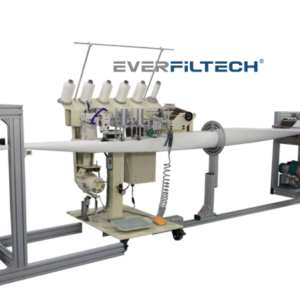

Automatic Sewing/ Hot Welding/ PTFE Tape Sealing Machine Line for Filter Bag

Fimedia Sewing Automatic Sewing Line for Filter Bag can meet the production requirements of sewing, gluing, hot melting, film pasting and other processes.

Max. Sewing speed: 10 m/min;

Suitable for stitching 120-300 mm diameter;

Capacity: 600pcs 6-meter-long filter bags in 8 hours.

We also supply semi-automatic sewing line, please click here!

We have the new whole machine catalogue, please click here!

We also have videos in the youtube, the link below.

https://www.youtube.com/channel/UCW3ondwLbuwy7FY6C0LMw7A

Description

Product Code: SY-L58000

Automatic Sewing/ Hot Welding/ PTFE Tape Sealing Machine Line for Filter Bag

Introduction

This automatic sewing line is a special newly developed and designed by our company for filter bags.

This line can meet the production requirements of various processes such as sewing, gluing, hot welding and PTFE taping.

Basic Parameters& Main function

| Item | Parameter |

| Configuration | 1Power:7.0 kw |

| 2Voltage:AC380V 3 Phase frequency:50HZ/60HZ | |

| 3-Size:16150mm(L)*1310mm(W)*1980mm(H) | |

| 4-Stiching speed:0-10m/min,hot welding speed:0~15m/min

PTFE tape sealing speed: 0-10m/min |

|

| 5-Compressed air :4~4.5kg/cm2 | |

| 6-Bag tube length: 0.8-9.0Meters | |

| 7.Stitching Tube diameter: 120-230mm | |

| 8.Hot welding diameter: 90-230mm | |

| 9.PTFE tape sealing diameter of tube : 120-230mm | |

| function | Stitching& Hot welding tubing & Bag tube PTFE tape sealing |

| Pneumatic cloth lifting and film stripping functions | |

| Filter material tension self-adjusting function, line break stop function | |

| Needle cooling function, backlight detection function | |

| Abnormal temperature alarm function | |

| Set length cutting function | |

| It can meet the needs of cutting filter bags of different lengths, such as cutting filter bags of different lengths from 0.8-9meters | |

| It can be used to produce ultra-low emission filter bags and meet the production needs of medical and food filter bags. | |

| Can meet the production needs of high, medium and low temperature filter bags, including PPS, PTFE, glass fiber and other filter bags | |

| The main body of the assembly line adopts aluminum profile structure, equipped with JUKI-MS1261 sewing machine imported from Japan, and adopts 1120mm extended lower arm design, which is particularly suitable for the hemming sewing requirements of PTFE filter bags. | |

| The production line is equipped with a brand new fabric forming mold, which is suitable for sewing filter bags of various specifications, with good forming effect and stable overlap width. | |

| The working rollers of the assembly line are covered with low-hardness polyurethane, which has good flexibility and is not easy to damage the PTFE film on the surface of the filter material | |

| The production line is equipped with high-power cutter motor and alloy steel blade, which can easily cut PTFE and glass fiber filter bags | |

| We use Delta series programmable control systems, servo control systems, and frequency conversion control systems, and the equipment failure rate is extremely low. |

Equipment Advantages

- The whole line can meet the production requirements of various processes such as sewing, gluing, hot welding, and PTFE taping.

- This line is equipped with a brand-new fabric forming mold, which is suitable for sewing or fusion of various specifications of filter bag body, with good forming effect and stable seam width.

- The sewing machine includes an automatic stop device for automatic detection of broken threads, and automatic stop when abnormal thread breaks.

- Adopt positioning device, precise film location; linkage work, automatic film application.

- Special heating device, the temperature can reach 700℃, the temperature fluctuates ±2℃, which can be applied to the film sealing of pure PTFE filter bag.

- This line includes a stripping machine and a film debris collection device, and the coated filter material can be fused.

- This line work roller is covered with low-hardness polyurethane, which has good flexibility and is not easy to damage the PTFE film on the surface of the filter material.

- The main body adopts aluminum profile structure, the installation is firm and stable, and the operation is stable.

- This line is equipped with high-power cutter motors and alloy steel blades, which can easily cut PTFE and glass fiber filter bags.

- Choose programmable control system, servo control system, frequency conversion control system, equipment failure rate is extremely low.